Our experience spans two dedicated websites.

Discover the world of Collaborative and Meeting Spaces:

Discover the world of Collaborative and Meeting Spaces:

Last update: 22/05/25

Prior to the mid-20th century, monitoring and controlling industrial equipment and remote sites largely relied on manual effort. The expansion to bigger sites led to the necessity for remote control solutions, initially through relays and timers. The advent of computing technology in the 1950s paved the way for more sophisticated supervised control methods. This technological evolution culminated in the development of SCADA systems in the 1970s, marking a significant milestone in the automation and efficient management of industrial operations.

Nowadays, these systems are indispensable in many industrial sectors for optimised and efficient management of operations.

But what is a SCADA system and what are its fields of application? This article reveals what you need to know about this key technology.

SCADA stands for Supervisory Control And Data Acquisition.

A SCADA system is mainly used for process supervision. It is an information system that performs the following functions:

> SCADA acts as a link between operational technology and information technology.

SCADA systems are essential for organizations that need to manage and control processes, notably within process industries such as chemicals, water distribution, and energy. However, their use is not limited to these areas; service industries, like fire brigade rescue centers, can also benefit from tailored SCADA solutions.

The versatility of SCADA systems allows them to be configured for both small entities and complex, large-scale industrial operations, demonstrating their adaptability across a wide range of organizational needs and sizes.

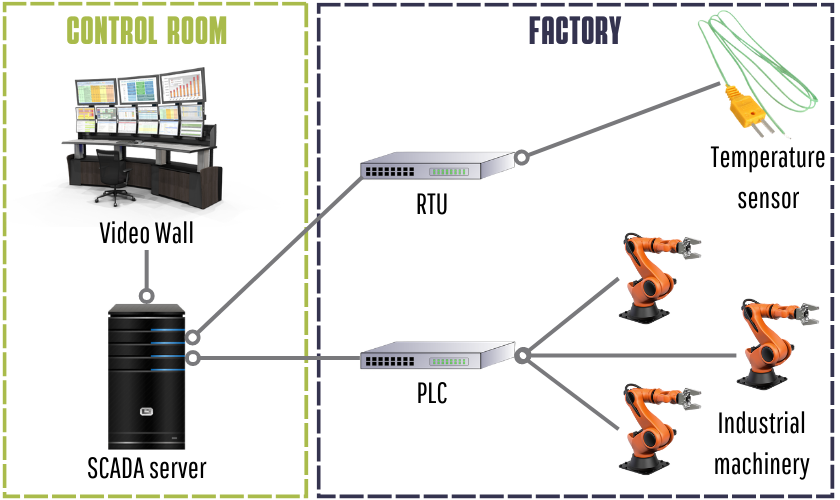

A typical SCADA system consists of a number of key elements working in synergy to ensure effective monitoring and control of industrial processes:

The HMI is the point of interaction between the human operator and the SCADA system. It provides a visual representation of industrial processes, displaying real-time data, trend graphs, alarms and reports. HMIs are designed to be intuitive, enabling operators to monitor their process easily and intervene quickly in the event of an incident.

Field Units and PLCs are devices deployed in the field and in electrical cabinets to collect data from sensors, instruments and other control devices. Field Units are often used in remote and harsh environments, while PLCs are more common in industrial environments. These devices transform analogue signals from sensors into digital data and transmit them to the central system.

The communications network is vital for transmitting the data collected by the Field Units/PLC to the SCADA control centre. This network can be based on a variety of technologies such as telephone lines, fibre optics, RJ45 cables, radio links, satellites and even the Internet. The reliability and security of this network is essential to ensure uninterrupted and secure data transmission.

The SCADA servers host the software that processes, analyses and stores the data received from the Field Units/PLCs. This software is the heart of the SCADA system, enabling real-time monitoring, process control, report generation and archiving of historical data. Modern SCADA software is highly customisable and can incorporate advanced modules such as artificial intelligence and machine learning for deeper analysis.

Databases play a crucial role in the storage and management of historical data. They enable users to retrieve historical data for trend analysis, process optimisation and strategic decision-making.

Security is a major concern in SCADA systems because of their critical importance. Security measures include firewalls, intrusion detection systems, encryption protocols and backup and disaster recovery strategies to protect the system against cyber attacks and outages.

SCADA is not just a monitoring and control tool, but a central pillar of operational intelligence. Its ongoing evolution is synonymous with growing opportunities for smarter, more sustainable industrial management.

As a general rule, the SCADA HMI is displayed on the main focus (video wall) of the control room.

Before it is installed, this video wall must therefore be thought through in terms of the different SCADA screens that are to be displayed: general image, details of a sub-process, etc.

SCADA systems have emerged as key components of Industry 4.0, transforming industrial operations through their capability to unify, automate, and enhance efficiency. They are pivotal in managing energy, facilitating predictive maintenance, and ensuring safety. At the heart of control rooms, they provide an essential, user-friendly interface for operators, marking a shift towards a smarter, more eco-friendly industrial landscape. Essentially, SCADA is more than just a technological asset; it is the cornerstone of strategic decision-making in modern industries.

Copyright © 2025. MOTILDE. All rights reserved.