The factory control room: an essential part of production monitoring

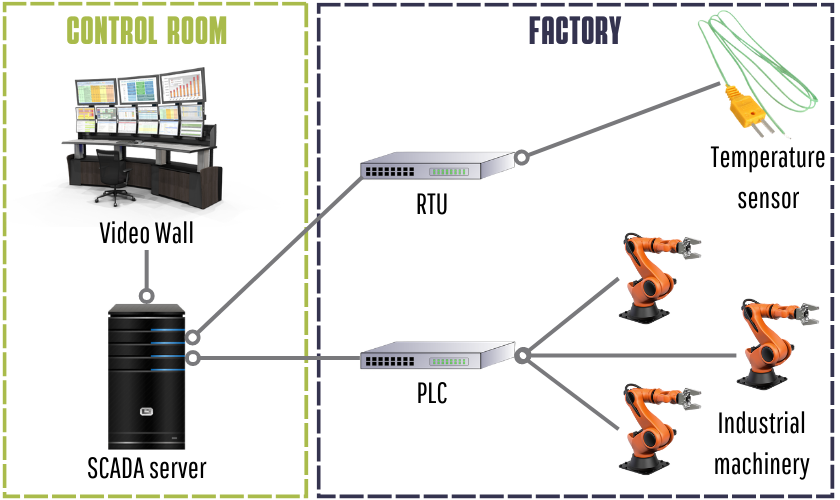

When considering improving the efficiency of plant operations, the main focus is on production, parcel tracking and operations management. Control rooms are an essential element for increasing the productivity of…