Last update: 19/05/25

Control and monitoring rooms are critical areas for many sectors, such as energy, logistics, security, factories, operating theatres and IT. Operators often spend long hours monitoring processes or locations that are often high-stakes, which can be stressful and tiring. Ergonomics is a crucial element in optimising the safety, productivity and well-being of these workers. In this article, we will look at how ISO 11064 can help improve control room ergonomics.

ISO 11064 was developed by the International Organization for Standardization (ISO) in response to a growing need for ergonomic design standards for control centres. This standard aims to improve the health, safety and well-being of control centre operators by providing recommendations for the design of workspaces that reduce fatigue, stress and health risks.

This standard is divided into 7 chapters:

One last important detail: the ISO 11064 standard is chargeable for each of these chapters.

The implementation of the recommendations set out in the ISO 11064 standard allows in particular :

The most important criteria according to the 11064 standard are:

According to ISO 11064, 9 principles should be considered for the ergonomic design of control centres:

In summary: In a user-centred approach, design starts with understanding the needs of the operator. End-users actively participate in the process by working with a multidisciplinary team to describe the tasks to be performed and the risks to be avoided. This information is then used as the basis for developing the right solution for their needs.

These principles include delineating work areas, estimating the size needed for each area, identifying the links between these areas, and creating a preliminary layout of the control room and adjacent areas to facilitate the transition between the different activities that will be carried out there.

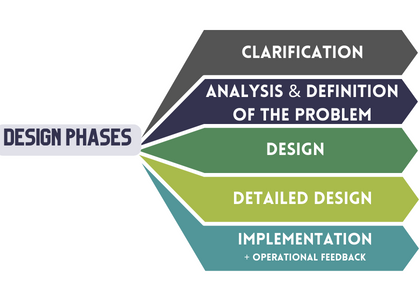

The design process of a control centre usually consists of several project phases, as follows:

This part of ISO 11064 focuses on the needs of users. The processes described have been designed to take these needs into account at every stage of the design process.

Again, the needs of the operator must be at the centre of the design of technical furniture. It is important here to take into account the ergonomic recommendations:

The objective of the human-machine interface is to maximise the safe, reliable, efficient and comfortable use of displays and graphics processors.

Lighting, acoustics, temperature, humidity and vibration are key factors influencing operator performance and comfort. For example, it is recommended to:

The final step in determining whether a control room design is successful is to conduct a post-occupancy evaluation after it has been commissioned. Operators provide feedback after having been involved in the project from the beginning. The lessons learned are then evaluated, documented and any recommendations for improvement are communicated.

All of these chapters of the standard provide a systematic method for ensuring the well-being of operators and the safety of the entire system. ISO 11064 is a central tool for all professionals working in the design of control rooms, as well as for those seeking to improve the safety and efficiency of critical operations.

Motilde will help you in the ergonomic design of your control or supervision room. To download the standard, go to the ISO website.

Copyright © 2026. MOTILDE. All rights reserved.